Homemade vs. Professional Machine Guards

Some machines can be dangerous by their very nature, even when they are used as intended. Daily work activity and heavy equipment can pose a significant risk to sensitive machinery. Despite the dangers, many manufacturers continue to sell machinery products without the controls and guards required by OSHA, giving a false sense of security.

If you have not fully familiarized yourself with the machine guarding requirements, you’re not alone. Understanding the many OSHA and ANSI regulations can be overwhelming, but they must be considered for the safety of your team and the security of your equipment.

What are Homemade Machine Guards?

Today, many leading machine shop floor managers are debating whether or not to build their own homemade machine guards or purchase them from a reputable manufacturer. OSHA requirements dictate that machine guards be in place for the safety of your crew, and the security of your clients and shareholders.

Building your own machine guards can seem like an attractive option. However, even experienced and properly equipped fabricators are rarely fully prepared to meet all of OSHA’s requirements, are prone to make mistakes, and subject to the inefficiencies that a professional machine guard manufacturer is fully prepared to mitigate.

Building your own machine guarding is bound to be more expensive, take more time, and often result in waste and mess, which can cause damage to sensitive equipment that can be avoided. Worst of all, should your homemade cage fail to meet OSHA safety standards, your efforts can all go to waste.

The Pitfalls of Homemade Machine Guards

- Homemade machine guards are rarely uniform in appearance and function.

- Performing the work in your facility is sure to create excessive waste and scrap, which contributes to dust and debris that can be a hazard to both people and machines.

- Creating your own cages leaves you with uncertainty while you wait for OSHA to approve your work. And if they don’t, you’ll have to start over from scratch.

- Whether you hire an engineer or perform the work yourself, it is unlikely that any fabricator not fully equipped and trained with optimized systems and processes to build professional machine guards won't be able to do so without incurring hidden costs. Engineers are overqualified for the task and are certain to overcharge you. On the other hand, building them yourself will force your team to deal with unpredictable logistics which will have to be dealt with in a timely manner.

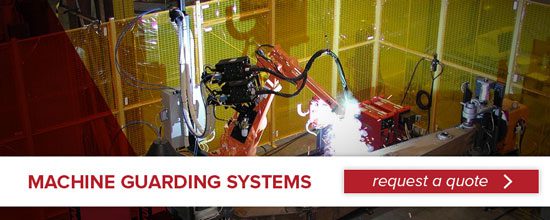

WireCrafters Machine Guarding System

When you let WireCrafters fulfill your machine guarding needs, you simply send our team the specifications for the machine guarding system you need. Our knowledgeable sales staff will work with you to create a fully customized and OSHA approved machine guard with no mess and no waste to clutter up your facility. You will receive expertly crafted modular and pre-drilled panels that are easy to assemble, strong, safe, and clean. It's really as easy as that!

To learn more about how our machine guarding experts can build a system to meet your needs with precision and strength, contact WireCrafters today. WireCrafters also offers stock material. Although our standard product is gray we can also provide black panels, yellow posts & hinge doors with Fortress interlocks all available in just one week shipping. Want to go ahead and get a free estimate? Request a quote here.

To learn more about our Machine Guarding Systems or get a quote, please click the image below.