Machine Guarding Systems

Versatile, Economical & Safe

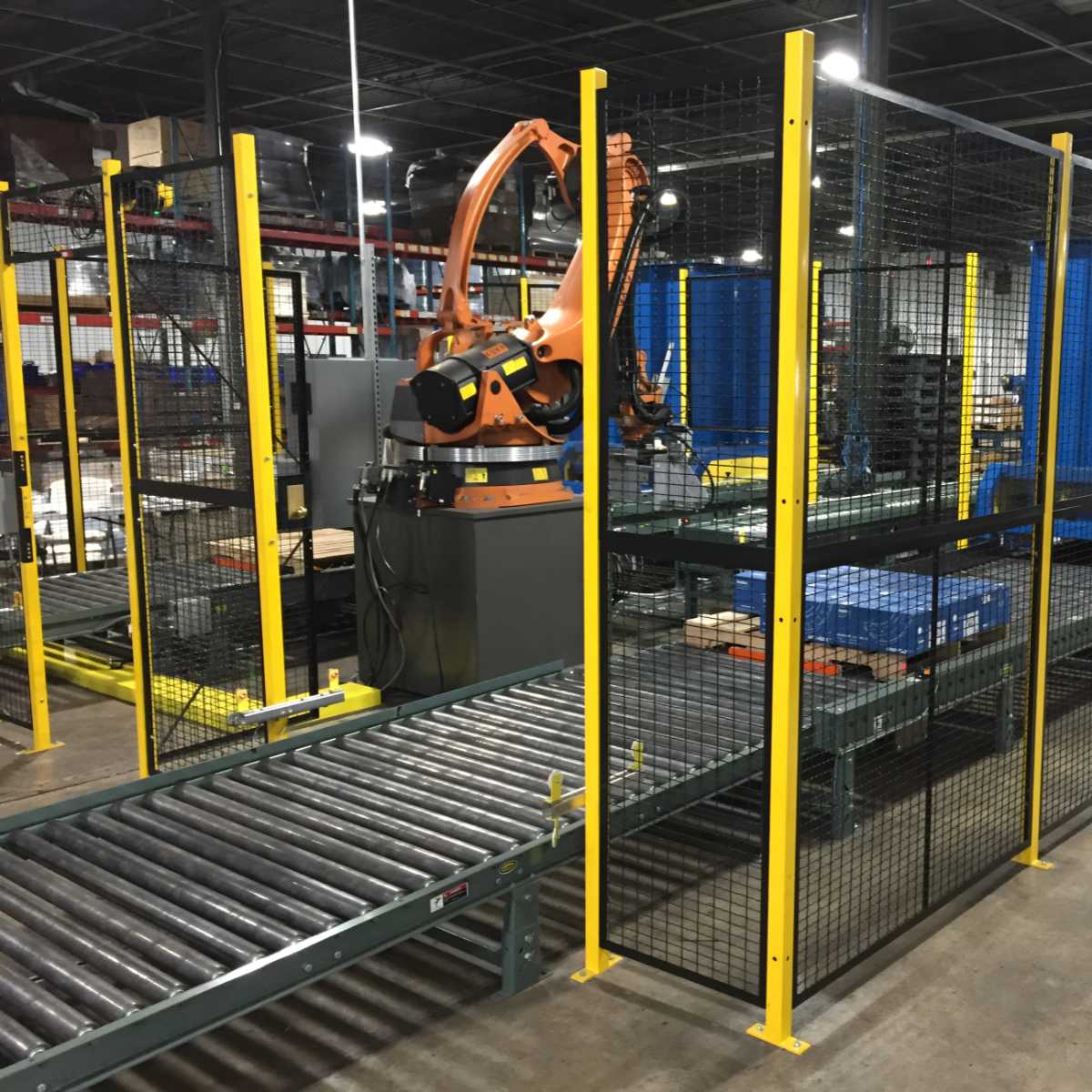

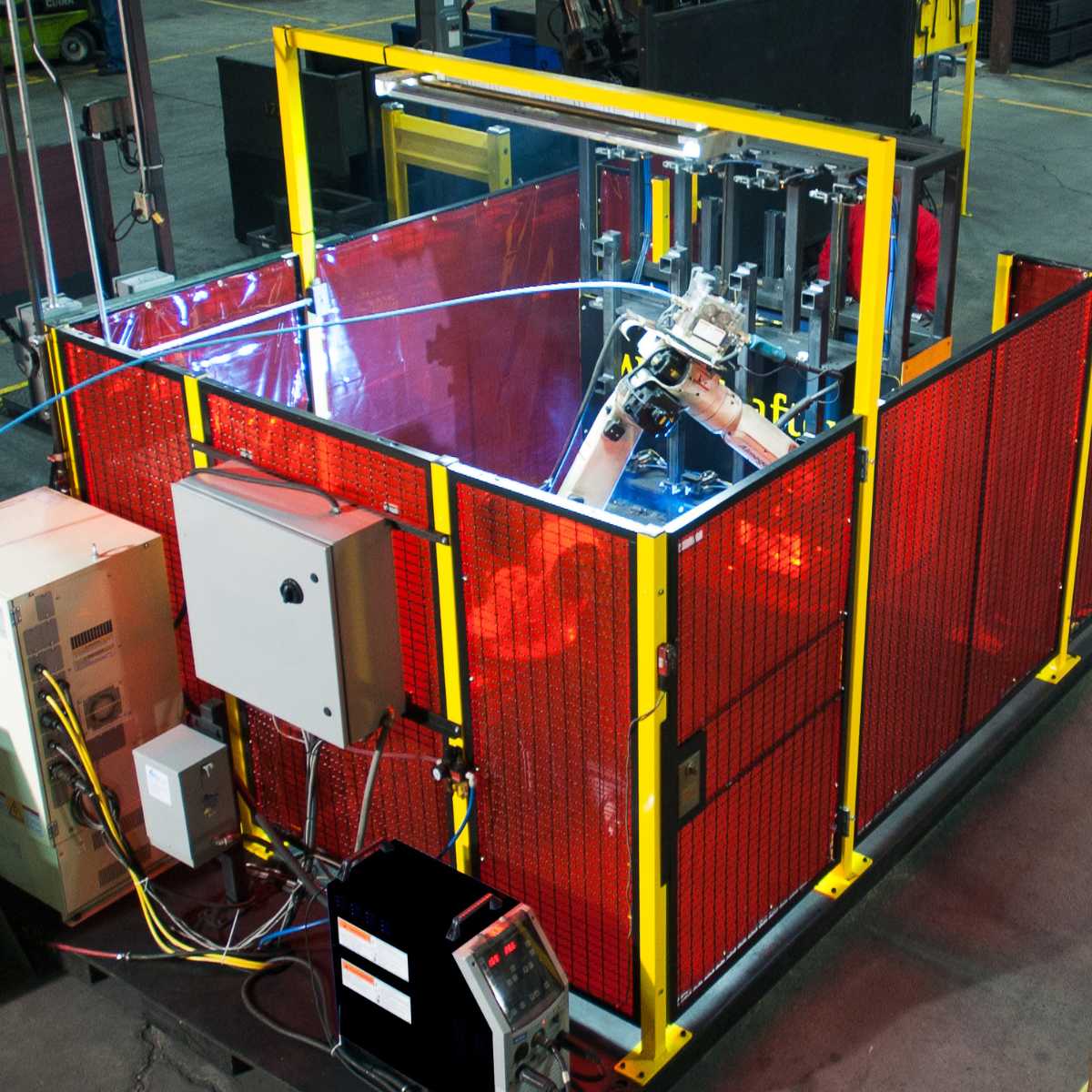

Machine Guarding Systems from WireCrafters® are a simple, effective way to protect personnel from the dangers posed by automated equipment. These barriers are a strong and economical solution to plant safety needs. Versatility of this system allows easy integration of access doors or larger openings with system controls.

Machine Guarding also doubles as a safety net by containing malfunctioning equipment. Welded and woven wire mesh is extremely resilient; it resists dings, retains its shape, and is virtually maintenance free.

These fully-framed woven wire or welded wire mesh panels bolt to posts forming a strong, secure barrier around dangerous automated equipment. Unlike high-tech light curtains and switch mats that are subject to electrical malfunctions, these safety systems are always on guard.

VARIETY OF PANEL OPTIONS

Woven wire, welded wire, expanded metal, polycarbonate, and sheet metal panels available.

INTERLOCKS

A variety of safety switches or interlocks can be supplied with mounting plates.

ENDLESS CUSTOMIZATION

WireCrafters® can tailor-make a guarding system that meets your rigorous safety standards.

Woven & Welded Wire Mesh Machine Guarding

WireCrafters® offers both woven and welded wire mesh machine guarding and perimeter guarding systems to protect and separate property, equipment, and personnel. WireCrafters® Machine Guarding Systems (or commonly referred to as Physical Barriers) are available in 5′, 8′, 10′ and 12′ or any height you require.

By the nature of its woven wire or welded wire design, WireCrafters® guarding systems provide an unparalleled level of safety and security. The traditional woven wire mesh machine guarding systems are constructed of a 10 GA wire, woven into a 2″ x 1″ rectangular mesh. This heavy mesh is welded inside a 1-1/4″ x 1-1/4″ x 1/8″ angle frame.

A more modern welded wire machine guarding system called RapidWireHD™ features a 10 GA welded wire design and is constructed in a 1 1/4″ x 2 1/2″ rectangular pattern. The sturdy welded mesh is surrounded by a 13 GA rolled formed angle frame. RapidWireHD™ is also available in a 2″x2″ welded mesh square pattern.

Alternate Machine Guarding Systems

Commonly woven and welded wire mesh machine guarding systems require solid partitions to be integrated into the systems design. WireCrafters® stocks solid sheet metal in 16 GA panels as well as 1/4″ Polycarbonate panels to complete your design. Expanded metal and stainless steel panels are also available for machine guarding.

Machine Guarding Applications

Commonly found in weld cells, robotic cells, press break equipment stations, laser cutting operation areas, metal stamping and folding areas, and punching stations, Machine Guarding, Area Guarding and Perimeter Guarding has hundreds, if not thousands of possible applications. Contact a knowledgeable dealer in your area to help define your machine guarding needs.

OSHA & ANSI/RIA R15.06-2014 Compliant

As the safeguarding standards for personnel and equipment continues to tighten WireCrafters® exists to mitigate the potential workplace hazards with improved machine guarding and physical barrier systems. We strive to be OSHA and ANSI/RIA compliant in all of our products.

Easily Customizable & Configurable

WireCrafters® machine guarding and perimeter guarding system utilize a modular wire mesh panel design which allows for multiple combinations of standard parts to meet your specific space and guarding requirements. We offer a full line of special colors and accessories such as hinged doors, sliding doors, lift out panels and locking latches to integrate with your machine guarding system.

The welded wire’s straight lines and inherent strength of either the woven or welded wire provide a strong, modern looking guard to complement your facility and equipment. WireCrafters® stocks a variety of meshes to meet requirements for heavy, medium, or light duty jobs.

WireCrafters® can tailor-make a guarding system that meets your rigorous safety standards.

RapidWire HD™, with its modular design, can be installed in 20% to 25% less time when compared to competing products. RapidWire HD™ is simple to plan, and easy to install.

Key Machine Guarding Features

- Standard height of 5′-3 1/4″ with 0′-3 1/4″ sweep & 8′-5 1/4″ with 0′-3 1/4″ sweep.

- Custom size panels and special heights available.

- Fully framed panel adds strength and stability unequaled in the industry.

- Hinged, double hinged, sliding and vertical rise doors available.

- Angle frame design gives installer clear access to hardware, speeding installation.

- Assembly hardware is inaccessible from the secured side of the guarding.

- All hardware including anchors included.

- Standard 3/8″ mounting hardware is the heaviest in the industry.

- Panels may be ordered in alternate woven and welded mesh options, expanded metal, sheet metal, or clear polycarbonate.

- Safety Interlocks available with mounting plates.

Related Posts

The Top 5 Benefits of Rapid Guard® II Machine Guarding

Machine Guarding, Safety, Security, Separation, Wire Partitions

Machine guarding is essential in maintaining a safe and productive work environment, particularly in industries with heavy machinery. At WireCrafters, we understand the importance of robust, reliable guarding systems that protect workers and enhance efficiency. Our Rapid Guard® II Machine Guarding system is a testament to this commitment, offering a blend of safety, convenience, and versatility that meets the rigorous demands of modern industrial facilities. We’ll explore the top five benefits of Rapid Guard® II, highlighting how it can revolutionize your approach to machine safety.

Read More

Maximizing Workplace Safety: An Introduction to Machine Guarding Applications

Machine Guarding, Safety, Security, Separation, Wire Partitions

In today’s industrial environment, ensuring employee safety is more critical than ever. Machine guarding is one of the most effective ways to protect employees from machinery hazards. This essential safety measure prevents accidents and keeps your operation compliant with OSHA standards.

Read More